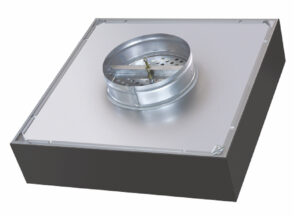

ROOM SIDE REPLACEABLE TERMINAL MODULES | CASINGS

Room Side Replaceable Terminal Side Laminar Flow Housings for Hospital / Pharma / Cleanroom application with diffusers.

| PRODUCT SPECIFICATIONS | |

|---|---|

| Category | Terminal HEPA Module-Ready to install Module or Filter Replacement Type |

| Housing Box material | Anodized and Extruded Aluminum Profile |

| Top Cover | Galvanized steel cover |

| Gasket | No gasket at outlet side |

| HEPA Filter | Gel Seal HEPA Filter or Gasket Type HEPA |

| Media | Micro Glass fiber |

| Media Separator | Hot melt glue |

| Filter-frame to media sealing | 2 component Polyurethane glue |

| Spigot | spigot Diameter of 250 mm/300mm depending on the airflow. The spigot is connected to flexible duct connector. The spigot height is 50 mm-100 mm. |

| Air Distribution Plate | Perforated Aluminum, screw adjustable distribution plate- Located at the plenum inlet collar for uniform air distribution |

| Diffuser (optional) | Perforated stainless steel or G.I Powder coated diffuser with hemmed edges (Without Diffuser is available) |

| Hanging Tabs | Built in Seismic holes are used for ceiling suspension (10mm Ø hole) |

| Test Port | Provided at filter central partition & accessible from room side by removing diffuser. Used for measuring filter replacement pressure drop |

| HEPA Grade as per EN 1822 | H13/H14/U15 |

| Recommended final pressure drop | 500 Pa |

| Maximum Temperature | 75º C |

| Maximum Relative Humidity | 90% |

| Filter installation & replacement | Room side replaceable filter by removing the diffuser plate. Channels provided to fix HEPA Filter & a fastening system clamps the HEPA filter inside the Box. |

| Performance Testing | Each terminal module shall be fully leak tested. |

Applications

• Pharmaceutical

• Biomedical

• Microelectronics

• Biotechnology

• Microbiology

• Research Labs

• Food Industry

• Nanotechnology

• Nuclear Industry

• LCD Manufacturing

• Medical Device Fabrication

• Semiconductor Fabrication

• Aerospace

• Healthcare

CONDO PHARMA

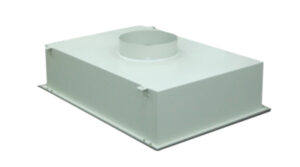

HEPA DUCTED LAMINAR FLOW TERMINAL MODULE | CASINGS

Laminar Flow Terminal Housing Box with Gel seal type or Gasket type HEPA filters for No Air-bypass construction for critical Applications.

| PRODUCT SPECIFICATIONS | |

|---|---|

| Category | Terminal HEPA Module-Replaceable HEPA type |

| Housing Box material | Galvanized steel or Mild Steel-Powder Coated /Stainless steel. Fully welded joints & Seams |

| Finish | RAL finish in various grade/epoxy coated-to prevent corrosion |

| Diffuser / Face Guard | Removable flush type with SS nuts or Hinged type. Type-Perforated/Swirl/adjustable vane/4-way diffusers |

| Spigot connection | Top inlet or Side inlet |

| Spigot | Ribbed circular spigot or square inlet connection on top. Inlet connections are continuously welded. |

| Air Distribution Plate (Optional) | Located at plenum inlet collar for uniform air distribution over filter air entry side. Plate made from SS/MS |

| Filter Installation & Mounting | Easily installed from room side by removing diffuser. Filter locking using quarter turn locks or quick clamping mechanisms with gasket compression inbuilt. |

| Volume Control Damper (Optional) | Provided at spigot side for controlling airflow. Damper is room side adjustable or adjustable from ceiling side. |

| Pressure Measurement port cum Aerosol Measurement (optional) | Measure filter replacement pressure drop at site & for upstream aerosol measurement |

| Aerosol Injection system (Optional) | Separate port for Aerosol injection from room side |

| Damper Control system (Optional) | Damper Operated from Room side by mechanical rod linkage |

| Aerosol Dispersion system (optional) | For even dispersion of aerosol over filter face area |

| Pressure Monitoring | DP switch for signaling filter replacement |

| Hanging Tabs | Fully welded hanging tabs used for ceiling suspension. 10mm Ø hole is provided for hanging. |

| Housing Box Insulation (Option) | Foil backed insulation-2” thick |

| Terminal Box Height | Standard height is 12”. Other Box height based on filter depths |

| Performance Testing | Each terminal module shall be fully leak tested. All welds and penetrations shall be bubble tested for leaks and must meet zero leak criteria. |

| Pre-Filter (Optional) | Additional chamber for Pre-Filter installation can be provided |

| HEPA Filter | Seamless PU Gasket type or Gel Seal type. Please refer Hepa filter technical catalogue for selection. |

| HEPA Grade as per EN 1822 | H13/H14/U15 |

| Maximum Pressure drop of filter | 450 Pa |

CONDO OPERA OT

LAMINAR FLOW UNIDIRECTIONAL OT FILTRATION MODULE | CASINGS

Laminar Flow Operation Theatre HEPA Housing with multiple arrays of HEPA filters with Diffusers for absolute Efficiency Filters.

| PRODUCT SPECIFICATIONS | |

|---|---|

| Category | Laminar HEPA Ceiling Terminal Module for Operation Theatre |

| Conformity Standards | ASHRAE / ASHE Standard-170; NFS 90-351 |

| Housing Box material | Stainless steel/ Galvanized steel or Mild Steel-Powder Coated. |

| Finish | SS 304/ RAL 9010 or equivalent grade to prevent corrosion |

| Design and Construction | As a single unit or as separate Modular Units. Each separate unit can be bolted together at site as a single unit. The joints are later mechanically sealed to be Leak proof & airtight. |

| Diffuser / Face Guard | Perforated type-SS Diffuser/ G.I or M.S Powder Coated. Fully Removable type or Hinged type. |

| Spigot connection | Lateral or Top spigot |

| Spigot | circular or Rectangular with Flanges |

| Central square or rectangular opening | For Surgical Light provision |

| Filter Installation & Mounting | Filter installed from room side by removing diffuser/ Hanging chains provided for hinged type diffuser. Filter locking using quarter turn locks or quick clamping mechanisms with gasket compression inbuilt. |

| Test port | Single Port per module to measure filter replacement pressure drop at site. |

| Pressure Monitoring | DP switch for signaling filter replacement |

| Hanging Clamps | Fully welded hanging Clamps used for ceiling suspension. |

| Performance Testing | Each Laminar OT module shall be fully leak tested. All welds and penetrations shall be bubble tested for leaks and must meet zero leakage criteria. |

| HEPA Filter | Seamless PU Gasket type or Gel Seal type. Please refer Hepa filter technical catalogue for selection. |

| HEPA Grade as per EN 1822 | H14 |

| Maximum Final pressure drop of filter | 500 Pa |

India Factory

AP Filtration Technologies

No.50, Jay Industrial Park,

SP Ring Road, Ahmedabad, Gujarat.

Contact Us

+91 9345362883

[email protected]

© 2025 APFILTECH. All Rights Reserved